Titanium Dioxide: the Difference between Sulphte Process and Chloride Process

There are two manufacturing processs for titanium dioxide: Sulphate Process and Chloride Process. Among them, 56% are chloride products, and more than 70% of these products are produced by large titanium dioxide factories such as DuPont in the United States. Titanium dioxide factories in other countries, including China, are still dominated by sulphate process.

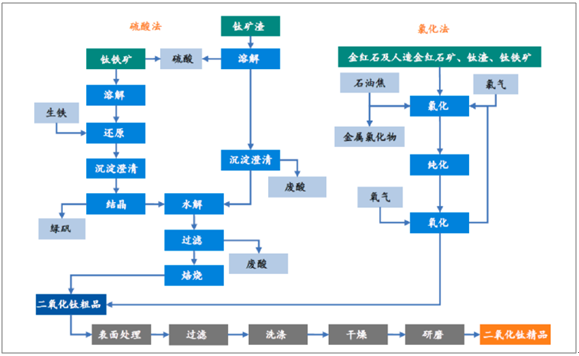

1] Sulphate Process

The titanium ferrous powder is subjected to acid hydrolysis reaction with concentrated sulphate to produce titanyl sulfate, which is hydrolyzed to generate metatitanic acid, and then calcined and pulverized to obtain titanium dioxide product. This process can produce anatase and rutile titanium dioxide. The advantage of the sulphate process is that it can use cheap and easily available ilmenite and sulphate as raw materials, the technology is relatively mature, the equipment is simple, and the anti-corrosion materials are easy to solve. The disadvantage is that the process is long, only intermittent operation is the main process, wet operation, high consumption of sulphate and water, many wastes and by-products, and great environmental pollution.

2] Chloride Process

The chloride process is to use titanium-containing raw materials to react with chlorine gas such as chlorinated high-titanium slag, artificial rutile, or natural rutile to generate titanium tetrachloride, which is purified by rectification, and then subjected to gas-phase oxidation; after rapid cooling, TiO2 is obtained through gas-solid separation. Because the TiO2 adsorbs a certain amount of chlorine, it needs to be removed by heating or steam treatment. The process is simple, but in chloride at 1000°C or higher, there are many chemical engineering problems such as high corrosion of chlorine, oxychloride, and titanium tetrachloride that need to be solved. In addition, the raw materials used are special, and the cost of the sulphate process is relatively low. high. chloride production is continuous production, the flexibility of the production unit operation is not large, and it is difficult to adjust the start-up and shutdown and production load, but its continuous process production, the process is simple, the process control points are few, and the product quality is easy to achieve optimal control. In addition, there is no sintering formed by the rotary kiln calcination process, and its TiO2 primary particles are easy to depolymerize, so people are used to thinking that the quality of the chloride process titanium dioxide products is better. The advantages of the chloride process are that the process is short, the production capacity is easy to expand, the degree of continuous automation is high, the energy consumption is relatively low, the "three wastes" are less, and high-quality products can be obtained. The disadvantage is that the investment is large, the equipment structure is complex, the material requirements are high, the high temperature resistance and corrosion resistance are required, the device is difficult to maintain, and the research and development is difficult.